The second of two huge tunnel boring machines has started digging the HS2 tunnels that’ll run under west London.

The HS2 railway out of Euston will run through tunnels until they reach West Ruislip, when they pop up for a few minutes of daylight before dropping back into tunnels under the Chilterns.

The long London tunnels are being dug in three phases, and the first phase is currently underway with tunnel boring machines starting work at West Ruislip and heading towards central London. Later, tunnels will be dug from the Old Oak Common station to meet the West Ruislip tunnels, and down towards Euston.

The tunnel portal site at West Ruislip has taken over a golf course, and where people used to walk around in bright garish clothing, now an army of construction workers walk around in bright hi-vis clothing.

Although much of the material needed to construct the tunnel can be brought in by rail as the site is conveniently next to the Chiltern Main Line, where other sites need to remove the tunnel muck from the site, here all the tunnelling soil will be reused later to landscape the golf course after all the construction workers have left.

It’s a long way from that though, and on a slightly wet day, the second of the TBMs at the site had the ceremonial button pressing that turned the huge machine on for the first time.

Although the first TBM, named Sushila launched a month ago, the machines are so long that the back is still poking out of the tunnel that it’s digging. And sitting next to it is Caroline, named after 18th century astronomer Caroline Herschel, waiting to get to work.

TBMs need to push against something to dig into the ground, so a large steel frame has been constructed in front of the tunnel wall, and as the machine gets started it will lay seven concrete rings to give it the mass needed to push against. Those seven rings will be removed later, and are just temporary to get the machines started.

The white TBM shield is pushing off its first set of tunnel rings – and the earlier TBM is now deep inside the soil within the completed tunnel rings int he distance.

A quirk of this particular site though is that the tunnels start very close to the surface. Normally, a tunnel portal is much deeper, but here it had to be closer to the surface, and that causes problems.

Although each tunnel ring weighs 52 tons, the soil removed weighs even more. When you remove heavy soil from the ground, the soil beneath it which had been crushed under the weight starts to expand. That causes anything built in the space, often basements, but here tunnels, to “heave” upwards. To stop the tunnel shifting as it’s dug, they’ve piled a huge amount of soil on top of where the tunnels are being dug to add the necessary weight. That weight of soil is a permanent feature, and will later be landscaped into a hill that will not just stop tunnel movement but will act as a sound barrier for local residents as trains enter and leave the tunnels.

But at the moment, it’s a huge shapeless mound of soil pushing down as the tunnel boring machines dig underneath.

Another preparation that was needed before the TBMs could get started was the delivery of more electricity. These machines eat a lot of fuel, and local power grids can’t support that sort of load, so a smaller tunnel was dug to deliver a new power cable to West Ruislip. After the tunnels are completed, apart from providing power to the railway it’ll also improve power supply flexibility in this part of west London for residents.

All the preparation work done, last week, TBM Caroline started her 5-mile journey under London when HS2’s Civils Delivery Director, Mike Lyons pressed the button in the control room that brought the machine to life. Just a few moments later everyone standing on the machine could feel the growling rumble and the cutting head at the front of the machine started rotating and cutting into London clay.

Michael Greiner, Head of Tunneling, Skanska Costain STRABAG JV and Mike Lyons, Civils Delivery Director, HS2

It wasn’t long before the long conveyor belts that run the length of the TBM had turned from pristine black to covered in muck as the clay flowed.

Each TBM is operated by 15 people, working in eight-hour shifts, with all the facilities they need from toilets to a canteen all included in the machine. There’s also a refuge chamber, should anything awful happen, and back at base, even a hypobaric chamber if it were ever to be needed.

Now that the second TBM has launched, it needs to dig the railway tunnel, and in the distance behind the tunnel portal, stacks of concrete segments are being piled up. Seven segments are needed for each tunnel ring, and in total 4,220 segments will be needed to dig each of the 5-mile tunnels. The segments are made on the Isle of Grain and delivered to West Ruislip by rail. Once at West Ruislip, a special vehicle drives each set of seven down the tunnel to the machine to be unloaded and later used to extend the tunnels towards Old Oak Common.

In case you’re interested, the first TBM is digging the Birmingham tunnel, while the TBM that launched last week is digging the London tunnel – as in the direction that the trains will be heading down them.

The two TBMs will be able to dig about 15 metres of tunnel per day when up to full speed, and should complete their initial 5-mile drive in 2024.

The second set of tunnels will take HS2 to Old Oak Common station, which when it opens in about 8 years time, will offer connections with the Elizabeth line and Great Western Railway, plus a short walk away to the London Overground, before then continuing to Euston station in central London.

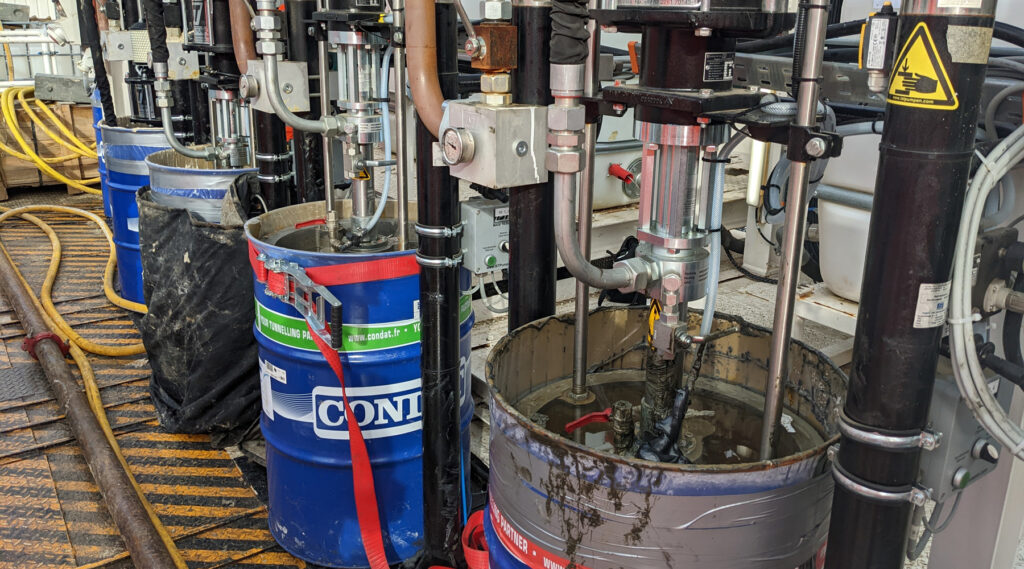

Some more photos from last week’s launch

An unappetising swiming pool – actually a sump to store water after heavy rain to be pumped away later without overloading local drains.

Close up of the inside of the TBM, where you can see the jacks that push the TBM forward pushing against the first tunnel rings

The site, showing the railway siding used for deliveries. The TBMs are behind the huge mound of soil on the right.

This article was published on ianVisits

SUPPORT THIS WEBSITE

This website has been running now for just over a decade, and while advertising revenue contributes to funding the website, but doesn’t cover the costs. That is why I have set up a facility with DonorBox where you can contribute to the costs of the website and time invested in writing and research for the news articles.

It’s very similar to the way The Guardian and many smaller websites are now seeking to generate an income in the face of rising costs and declining advertising.

Whether its a one-off donation or a regular giver, every additional support goes a long way to covering the running costs of this website, and keeping you regularly topped up doses of Londony news and facts.

If you like what your read on here, then please support the website here.

Thank you

The post A second HS2 tunnel boring machine starts digging under London appeared first on ianVisits.